Ball valves Elephant BV3131P(3pc)-FP-F-ISO-H flanged, full bore, three-piece, stainless steel body. steel SS304, seal - PTFE, with pneumatic actuator Elephant PA-SA 065-160 pneumatic distributor 4V320-10 ATU AFC2000 APL-510N-EX

Ball valves Elephant BV3131P(3pc)-FP-F-ISO-H flanged, full bore, three-piece, stainless steel body. steel SS304, seal - PTFE, with pneumatic actuator Elephant PA-SA 065-160 pneumatic distributor 4V320-10 ATU AFC2000 APL-510N-EX - DN100 / 16 bar is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

The delivery cost is determined during the checkout process and varies based on several factors, including the product type, delivery time, service provider, and destination country.

Description

Description

The ball valve is used as a shut-off valve in heat supply systems, water supply systems, in steam, fuel and pneumatic systems with compressed air and neutral gases. Installation of valves of this series is possible in systems transporting liquid and gaseous media (water, oil, oils, steam, air, alcohols, glycol, etc.), non-aggressive to the materials of the valve.

Pneumatic actuators PA-SA are designed to automate the process of controlling industrial shut-off valves - valves, ball valves. Pneumatic actuators Elephant are designed for use both indoors and outdoors. All internal and external parts have an anti-corrosion coating.

Pneumatic distributors 4V320-10 220 V are used for control in pneumatic systems with a NAMUR mating surface for installing distributors through through holes in the housing.

The AFC2000 air preparation unit is designed to clean compressed air from droplet moisture and solid particles, remove condensate, automatically maintain the pressure at a given level, supply lubricant from the tank to the compressed air flow to the pneumatic system elements with a large range of throughput from 500 liters/minute to 10,000 liters/minute. The lubricator (oil sprayer) adds oil with a viscosity of 32 mm²/s (=cSt) at 40°C to the pneumatic system for further lubrication of control components - pneumatic cylinders and pneumatic distributors.

The Elephant APL-510N-EX limit switch unit is an electrical device designed to open and close the working circuit and to visualize the positions of the shut-off element of pipeline valves. As a rule, a sealed box contains two mechanical switches rated for up to 250 V, which monitor the position of the actuator rod and signal in extreme positions. They are mounted on top of the actuator surface. In the upper part of the limit switch unit there is a two-color hemisphere of the visual indicator. If the connected pipeline valve is closed, then only the red part of the hemisphere with the inscription CLOSED is visible; if open, only the yellow part with the inscription OPEN. This visual indicator is clearly visible from afar, which simplifies the inspection of the equipment, and the color difference between the open and closed positions reduces the likelihood of erroneous perception of information. Thanks to the use of the LSU, it becomes possible to transmit information about the position of pipeline valves (open/closed) to automated control systems, which increases the reliability of the system as a whole and simplifies diagnostics when faults are detected.

Technical data of ball valves Elephant BV3131P(3pc)-FP-F-ISO-H PA-SA 4V320-10 220V APL-510N Ex AFC2000

| Nominal diameter DN, mm | 40 – 300 |

| Nominal pressure PN, MPa (kg/cm2) | 1.6 (16) |

| Direction of flow | bilateral |

| Temperature of working environment t, ⁰C |

-20 to +85 for NBR -20 to +120 for EPDM -10 to +180 for PTFE |

| Working environment |

EPDM: cold and hot water, air without impurities of oil and fat, other environments neutral to the material PTFE: water, alkalis, acids, solvents and oxidizers NBR: water, mineral oils, hydrocarbons, oils, fats |

| Connection to the pipeline | interflange |

Sketch of detailing of ball valves Elephant BV3131P(3pc)-FP-F-ISO-H PA-SA 4V320-10 220V APL-510N Ex AFC2000

Materials of parts of ball valves Elephant BV3131P(3pc)-FP-F-ISO-H PA-SA 4V320-10 220V APL-510N Ex AFC2000

| No. | Name | Material | Quantity |

| 1 | Frame | SS304 | 1 |

| 2 | Ball valve | SS304 | 1 |

| 3 | Bolt | S201 | 4-6 |

| 4 | screw | S201 | 6-12 |

| 5 | Sealing | PTFE | 1 |

| 6 | Stock | SS304 | 1 |

| 7 | Seal | SS201 | 1 |

| 8 | Lid | WCB/CF8/CF8M | 2 |

| 9 | Saddle rings | PTFE | 2 |

| 10 | Thrust washer | PTFE | 1 |

| 11 | screw | SS201 | 1 |

| 12 | Lever | SS201 | 1 |

| 13 | Handle shell | PVC | 1 |

| 14 | Stopper | SS201 | 1 |

Sketch of ball valves Elephant BV3131P(3pc)-FP-F-ISO-H PA-SA 4V320-10 220V APL-510N Ex AFC2000

Overall and installation dimensions of ball valves Elephant BV3131P(3pc)-FP-F-ISO-H PA-SA 4V320-10 220V APL-510N Ex AFC2000

| DN | d, mm | D, mm | D1, mm | D2, mm | W, mm | f, mm | L±1.5, mm | T, mm | H, mm | Z-øM pcs-mm |

| 15 | 15 | 95 | 65 | 46 | 17 | 2 | 130 | 131 | 71 | 4-ø14 |

| 20 | 20 | 105 | 75 | 58 | 18 | 2 | 150 | 131 | 74 | 4-ø14 |

| 25 | 25 | 115 | 85 | 68 | 18 | 2 | 160 | 167 | 97 | 4-ø14 |

| 32 | 32 | 140 | 100 | 78 | 19 | 2 | 180 | 167 | 110 | 4-ø18 |

| 40 | 40 | 150 | 110 | 88 | 19 | 2 | 200 | 193 | 117 | 4-ø18 |

| 50 | 50 | 165 | 125 | 102 | 19 | 3 | 230 | 193 | 125,5 | 4-ø18 |

| 65 | 65 | 185 | 145 | 122 | 22 | 3 | 290 | 242 | 135,5 | 8-ø18 |

| 80 | 80 | 200 | 160 | 140 | 24 | 3 | 310 | 272 | 157 | 8-ø18 |

| 100 | 100 | 234 | 190 | 161 | 24 | 3 | 350 | 295 | 181 | 8-ø22 |

| 100* | 100 | 220 | 180 | 158 | 20 | 3 | 350 | 330 | 169 | 8-ø18 |

Technical data of SA pneumatic actuators with return springs:

| Type of pneumatic actuator | SA - with return springs |

| Nominal pressure PN, bar | 12 |

| Working pressure, bar | 2...8 |

| Working medium | filtered compressed air |

| Maximum particle diameter of the working medium, µm2 | ≤30 |

| Ambient temperature, ⁰C | -20 to +80 |

| Swivel angle, ° | 0 - 90 |

| Swivel angle adjustment, % | ±5 |

| Position indicator | open/closed |

| Top connection standard | NAMUR |

| Air connection standard | NAMUR |

| Average life, cycles closed/open | 70 000 (for non-aggressive media and medium pressure and temperature values) |

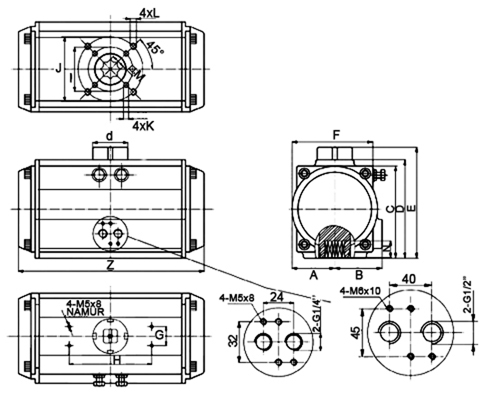

SA pneumatic actuators rotary with return springs

Dimensions and mounting dimensions of SA pneumatic actuators with return springs:

| Model | A, mm | B, mm | C, mm | D, mm | E, mm | F, mm | G, mm | H, mm |

| PA-x-052 | 30 | 41,5 | 65,5 | 72 | 92 | 65 | 30 | 80 |

| PA-x-065 | 36 | 47 | 81 | 88 | 108 | 72 | 30 | 80 |

| PA-x-083 | 46 | 57 | 98,5 | 108,7 | 128,7 | 92 | 30 | 80 |

| PA-x-105 | 57,5 | 64 | 122,5 | 133 | 153 | 109,5 | 30 | 80 |

| PA-x-130 | 67,5 | 74,5 | 145,5 | 155 | 185 | 127,5 | 30 | 130 |

| PA-x-140 | 75 | 77 | 161 | 172 | 202 | 137,5 | 30 | 130 |

| PA-x-160 | 87 | 87 | 184 | 197 | 227 | 159 | 30 | 130 |

| PA-x 210 | 113 | 113 | 235,5 | 255 | 285 | 210 | 30 | 130 |

| PA-x-270 | 147 | 147 | 299 | 326 | 356 | 273 | 30 | 130 |

| PA-x-300 | 162 | 174 | 330 | 350 | 380 | 312 | 30 | 130 |

| PA-x-350 | 190 | 195 | 483 | 410 | 440 | 365 | 30 | 130 |

| Model | A, mm | B, mm | C, mm | D, mm | E, mm | F, mm | G, mm | H, mm |

| PA-x-052 | 30 | 41,5 | 65,5 | 72 | 92 | 65 | 30 | 80 |

| PA-x-065 | 36 | 47 | 81 | 88 | 108 | 72 | 30 | 80 |

| PA-x-083 | 46 | 57 | 98,5 | 108,7 | 128,7 | 92 | 30 | 80 |

| PA-x-105 | 57,5 | 64 | 122,5 | 133 | 153 | 109,5 | 30 | 80 |

| PA-x-130 | 67,5 | 74,5 | 145,5 | 155 | 185 | 127,5 | 30 | 130 |

| PA-x-140 | 75 | 77 | 161 | 172 | 202 | 137,5 | 30 | 130 |

| PA-x-160 | 87 | 87 | 184 | 197 | 227 | 159 | 30 | 130 |

| PA-x 210 | 113 | 113 | 235,5 | 255 | 285 | 210 | 30 | 130 |

| PA-x-270 | 147 | 147 | 299 | 326 | 356 | 273 | 30 | 130 |

| PA-x-300 | 162 | 174 | 330 | 350 | 380 | 312 | 30 | 130 |

| PA-x-350 | 190 | 195 | 483 | 410 | 440 | 365 | 30 | 130 |

Sketch of dimensions of SA pneumatic actuators with return springs

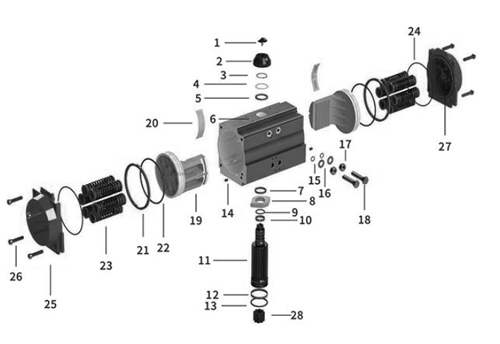

Materials of parts of SA pneumatic actuators with return springs:

| № | Part name | Material |

| 1 | Indicator screw | ABS plastic |

| 2 | Position indicator | ABS plastic |

| 3 | Spring clip | stainless steel 304 |

| 4 | Metal washer | stainless steel 304 |

| 5 | Pressure washer | engineering plastic |

| 6 | Housing | hard anodized extruded aluminum alloy |

| 7 | Pressure washer | engineering plastic |

| 8 | Limiter | alloy steel |

| 9 | Shaft sealing ring upper | NBR |

| 10 | Upper shaft sliding ring | engineering plastic |

| 11 | Shaft | nickel plated alloy steel |

| 12 | Shaft sliding ring lower | engineering plastic |

| 13 | Shaft O-ring lower | NBR |

| 14 | Plug | NBR |

| 15 | Seal ring of adjusting screws | NBR |

| 16 | Washer of adjusting screw | stainless steel 304 |

| 17 | Lock nut of adjusting screw | stainless steel 304 |

| 18 | Adjusting screw | stainless steel 304 |

| 19 | Piston | die-cast aluminum alloy |

| 20 | Piston guide plate | engineering plastic |

| 21 | Piston sliding ring | engineering plastic |

| 22 | Piston O-ring | NBR |

| 23 | Spring set | spring steel |

| 24 | Cover O-ring | NBR |

| 25 | End cap | cast aluminum with polyester coating |

| 26 | Cover screw | stainless steel 304 |

| 27 | Stop screw | stainless steel 304 |

| 28 | Adapter | carbon steel |

Material sketch of SA pneumatic actuators with return springs

Technical characteristics of the pneumatic distributor 4V320-10 220 V

| Name | Meaning |

| Type of pneumatic distributor | spool valve |

| Body material | aluminum alloy and technopolymer |

| Control | two-way electromagnetic |

| Scheme of work |

5/2 5 working lines; 2 positions |

| Effective cross-sectional area, mm2 |

model 4V320-8 – 25 (Cv = 1.4) model 4V320-10 – 30 (Cv = 1.68) |

| Thread of working ports |

model 4V320-8 – G 1/4" model 4V320-10 – G 3/8" |

| Exhaust port thread |

model 4V320-8 – G 1/4" model 4V320-10 – G 1/4" |

| Working pressure, bar | 1.5 ÷ 8 |

| Maximum pressure, bar | 12 |

| Working environment |

purified air (filtration fineness 40 microns) |

| Supply voltage, V | 220 |

| Full power, V A | 4.5 |

|

Permissible changes in supply voltage |

±10% |

| Degree of protection/insulation class | IP65/F |

| Operating temperature, °C | from -5 to +50 |

| Maximum response frequency | 5 cycles per second |

| Minimum switching time, s | 0.05 |

| Flow rate, l/min |

model 4V320-8 – 1,350 model 4V320-10 – 2,250 |

| Average resource, cycles | 20,000,000 |

| Weight, kg | 1,2 |

Main parameters of the air preparation unit AFC2000

| Working pressure, bar | 8 |

| Maximum pressure, bar | 10 |

| Adjustable pressure range, bar | 0.5 ÷ 9 |

| Destruction pressure, bar | 15 |

| Air connection | 1/4" |

| Operating temperature, C | from -5 to +60 |

| Size of filtered particles, µm | 40 |

| Oil viscosity | ISO VG 32 |

| Weight, kg | 0.395 |

| Kit composition | filter-moisture separator, pressure regulator, lubricator, bracket |

Characteristics of the APL-510N-EX limit switch unit

| Parameter | Meaning |

| Frame |

All-weather IP67/ NEMA4 4X,7,9 explosion-proof E EX d IIC T6 |

| Compatible devices |

- quarter-turn pneumatic actuators; - any actuators with a shaft rotation of 90° |

| Full rotation angle | 90° |

| Cable entries | 2 x NPT 3/4” |

| Electrical connection | screw clamp terminals 8 points (0.08 – 2.5) mm2 |

| Cable entry thread | 2 x NPT 3/4” |

| Visual indicator type | two-color hemisphere: OPEN - yellow CLOSED - red |

| Switches/sensors | two mechanical switches two proximity sensors |

| Nominal voltage, V | 250 |

| Rated current, A | 16 |

| Permissible ambient temperature, °C | from -20 to +66 |

| Average resource, cycles | 10,000,000 |

| Weight, kg | 1.8 |

Specifications

Specifications

-

Country of origin

-

Port opening

-

Body material

-

Maximum allowable temperature

-

Connection type

-

Control type

-

Operating environmentWater, Steam, Oil Products, Liquid Media, Neutral Media, Gaseous Media

-

Type of seal

-

Voltage

-

Explosion-proof

-

Torque

-

Limit switches

-

Type of pneumatic actuator

Reviews (0)

Reviews (0)

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Frequently Asked Questions

Shipping

What countries do you ship to?

What countries do you ship to?

We currently offer shipping within France and across the EU, as well as international shipping options. If you have a specific destination in mind that is not listed, please don’t hesitate to contact us for more information.

How long will it take to receive my order?

How long will it take to receive my order?

Standard shipping normally takes 3-7 days. Next day shipping is available on all domestic orders (for an additional charge). International shipping times depend on the products and destination (estimated at checkout).

Returns and Refunds

How do I return a product?

How do I return a product?

Items must be returned within 30 days after receiving your order. Items must be returned in the same condition in which they were received, be unworn/unused, have any tags still attached, and include all the original packaging.

How long will it take to receive my refund?

How long will it take to receive my refund?

Refunds are processed within 7 days from when we receive the item(s).