Ball valves Elephant BV3232P(4pc)-FP-3WL-F-ISO-H 16 bar full bore, flanged, body - stainless steel SS316, ISO flange F03/F04-F10/F12, square 9x9-19x19, with pneumatic drive PA-SA, pneumatic valve 4M310-08 220V, LSU APL-410N EX and ATU AF

Ball valves Elephant BV3232P(4pc)-FP-3WL-F-ISO-H 16 bar full bore, flanged, body - stainless steel SS316, ISO flange F03/F04-F10/F12, square 9x9-19x19, with pneumatic drive PA-SA, pneumatic valve 4M310-08 220V, LSU APL-410N EX and ATU AF - DN100 / 16 bar is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

The delivery cost is determined during the checkout process and varies based on several factors, including the product type, delivery time, service provider, and destination country.

Description

Description

The ball valve is used as a shut-off valve in heating, water supply, steam, fuel and pneumatic systems with compressed air and neutral gases. Installation of valves of this series is possible in systems transporting liquid and gaseous media (water, oil, oils, steam, air, alcohols, glycol, etc.) not aggressive to valve materials.

Pneumatic Elephant rotary actuators with return spring PA-SA are designed for automation of industrial valve control process with maximum torque up to 2128 Nm.

Technical parameters of ball valves Elephant BV3232P(4pc)-FP-3WL-F-ISO-H 16 bar full bore, flanged, body - stainless steel SS316

| Parameter | Value |

|---|---|

| Nominal Pressure PN, bar | 16 |

| Operating Temperature, °C | -25 to 180 |

| Valve Type | Three-way |

| Three-way Valve Type | L |

| Application | Water supply, heating supply |

| Operating Medium | Water, steam, petroleum products, neutral and gaseous media |

| Pipeline Connection | Flanged |

| Water-drawing | No |

| Flow Section Type | Full bore |

| Tightness Class | A |

| Control Type | Pneumatic actuator |

| Connection Type | Flanged |

| Actuation | Pneumatic actuator with return springs |

| Limit Switches | Yes |

| Pneumatic Distributor | Yes |

| Electropneumatic Positioner | No |

| Average Service Life, years | 10 |

| Warranty, years | 1 |

| Country of Manufacture | China |

Dimensions and dimensions of ball valves Elephant BV3232P(4pc)-FP-3WL-F-ISO-H 16 bar full bore, flanged, body - stainless steel SS316

| DN | d, mm | d1, mm | k, mm | D, mm | L, mm | H, mm | W, mm | T, mm |

| 15 | 15 | 45 | 65 | 95 | 150 | 72 | 150 | 14 |

| 20 | 18 | 58 | 75 | 105 | 160 | 77 | 190 | 14 |

| 25 | 25 | 64 | 85 | 115 | 180 | 82 | 190 | 14 |

| 32 | 32 | 78 | 100 | 140 | 200 | 100 | 215 | 16 |

| 40 | 38 | 88 | 110 | 150 | 220 | 108 | 215 | 16 |

| 50 | 49 | 99 | 125 | 165 | 240 | 125 | 250 | 18 |

| 65 | 65 | 122 | 145 | 185 | 260 | 144 | 250 | 18 |

| 80 | 80 | 138 | 160 | 200 | 280 | 160 | 300 | 20 |

| 100 | 100 | 158 | 180 | 220 | 325 | 187 | 300 | 20 |

| DN | D1, mm | D2, mm | D3, mm | D4, mm | SxS, mm | N – Z, mm | ISO 5211 | Weight, kg |

| 15 | 5,5 | 6 | 36 | 42 | 9х9 | 4 –14 | F03/F04 | 3,5 |

| 20 | 6,0 | 7 | 42 | 50 | 11х11 | 4 –14 | F04/F05 | 4,5 |

| 25 | 6,0 | 7 | 42 | 50 | 11х11 | 4 –14 | F04/F05 | 5,6 |

| 32 | 7,0 | 9 | 50 | 70 | 14х14 | 4 –18 | F05/F07 | 9,3 |

| 40 | 7,0 | 9 | 50 | 70 | 14х14 | 4 –18 | F05/F07 | 11,65 |

| 50 | 9,0 | 11 | 70 | 102 | 17х17 | 4 –18 | F07/F10 | 17,95 |

| 65 | 9,0 | 11 | 70 | 102 | 17х17 | 4 –18 | F07/F10 | 26,5 |

| 80 | 9,0 | 11 | 70 | 102 | 19х19 | 8 –18 | F07/F10 | 39,1 |

| 100 | 11,0 | 13 | 102 | 125 | 19х19 | 8 –18 | F10/F12 | 58,5 |

Table of parts and materials for ball valves Elephant BV3232P(4pc)-FP-3WL-F-ISO-H 16 bar full bore, flanged, body - stainless steel SS316

| № | Part Name | Material |

|---|---|---|

| 1 | Body | Stainless Steel SS316 |

| 2 | Ball | Stainless Steel SS316 |

| 3 | Seal | PTFE |

| 4 | Body Cover | Stainless Steel SS316 |

| 5 | Bolt | Stainless Steel SS304 |

| 6 | Gasket | PTFE |

| 7 | Nut | Stainless Steel SS304 |

| 8 | Gasket | PTFE |

| 9 | Stem Seal | PTFE |

| 10 | Bolt | Stainless Steel SS304 |

| 11 | Packing Gland | Stainless Steel SS304 |

-fp-3x-f-h-naboryi.jpg)

Parts and materials sketch for ball valves Elephant BV3232P(4pc)-FP-3WL-F-ISO-H 16 bar full bore, flanged, body - stainless steel SS316

Technical data of SA pneumatic actuators with return springs:

| Type of pneumatic actuator | SA - with return springs |

| Nominal pressure PN, bar | 12 |

| Working pressure, bar | 2...8 |

| Working medium | filtered compressed air |

| Maximum particle diameter of the working medium, µm2 | ≤30 |

| Ambient temperature, ⁰C | -20 to +80 |

| Swivel angle, ° | 0 - 90 |

| Swivel angle adjustment, % | ±5 |

| Position indicator | open/closed |

| Top connection standard | NAMUR |

| Air connection standard | NAMUR |

| Average life, cycles closed/open | 70 000 (for non-aggressive media and medium pressure and temperature values) |

SA pneumatic actuators rotary with return springs

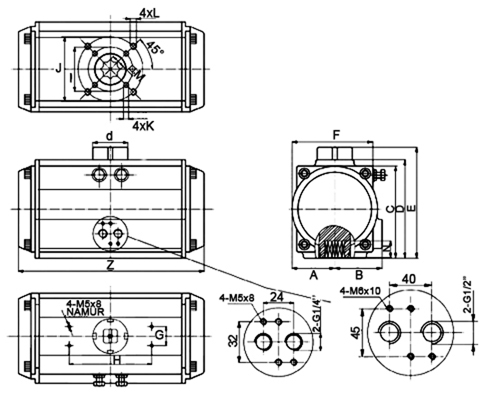

Dimensions and mounting dimensions of SA pneumatic actuators with return springs:

| Model | A, mm | B, mm | C, mm | D, mm | E, mm | F, mm | G, mm | H, mm |

| PA-x-052 | 30 | 41,5 | 65,5 | 72 | 92 | 65 | 30 | 80 |

| PA-x-065 | 36 | 47 | 81 | 88 | 108 | 72 | 30 | 80 |

| PA-x-083 | 46 | 57 | 98,5 | 108,7 | 128,7 | 92 | 30 | 80 |

| PA-x-105 | 57,5 | 64 | 122,5 | 133 | 153 | 109,5 | 30 | 80 |

| PA-x-130 | 67,5 | 74,5 | 145,5 | 155 | 185 | 127,5 | 30 | 130 |

| PA-x-140 | 75 | 77 | 161 | 172 | 202 | 137,5 | 30 | 130 |

| PA-x-160 | 87 | 87 | 184 | 197 | 227 | 159 | 30 | 130 |

| PA-x 210 | 113 | 113 | 235,5 | 255 | 285 | 210 | 30 | 130 |

| PA-x-270 | 147 | 147 | 299 | 326 | 356 | 273 | 30 | 130 |

| PA-x-300 | 162 | 174 | 330 | 350 | 380 | 312 | 30 | 130 |

| PA-x-350 | 190 | 195 | 483 | 410 | 440 | 365 | 30 | 130 |

| Model | A, mm | B, mm | C, mm | D, mm | E, mm | F, mm | G, mm | H, mm |

| PA-x-052 | 30 | 41,5 | 65,5 | 72 | 92 | 65 | 30 | 80 |

| PA-x-065 | 36 | 47 | 81 | 88 | 108 | 72 | 30 | 80 |

| PA-x-083 | 46 | 57 | 98,5 | 108,7 | 128,7 | 92 | 30 | 80 |

| PA-x-105 | 57,5 | 64 | 122,5 | 133 | 153 | 109,5 | 30 | 80 |

| PA-x-130 | 67,5 | 74,5 | 145,5 | 155 | 185 | 127,5 | 30 | 130 |

| PA-x-140 | 75 | 77 | 161 | 172 | 202 | 137,5 | 30 | 130 |

| PA-x-160 | 87 | 87 | 184 | 197 | 227 | 159 | 30 | 130 |

| PA-x 210 | 113 | 113 | 235,5 | 255 | 285 | 210 | 30 | 130 |

| PA-x-270 | 147 | 147 | 299 | 326 | 356 | 273 | 30 | 130 |

| PA-x-300 | 162 | 174 | 330 | 350 | 380 | 312 | 30 | 130 |

| PA-x-350 | 190 | 195 | 483 | 410 | 440 | 365 | 30 | 130 |

Sketch of dimensions of SA pneumatic actuators with return springs

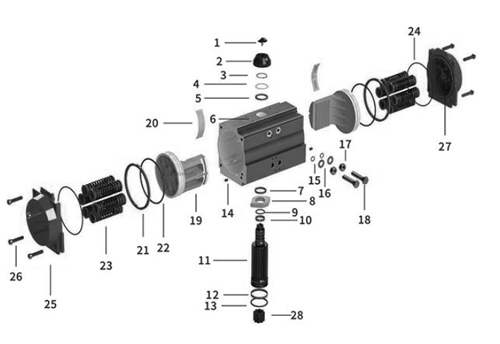

Materials of parts of SA pneumatic actuators with return springs:

| № | Part name | Material |

| 1 | Indicator screw | ABS plastic |

| 2 | Position indicator | ABS plastic |

| 3 | Spring clip | stainless steel 304 |

| 4 | Metal washer | stainless steel 304 |

| 5 | Pressure washer | engineering plastic |

| 6 | Housing | hard anodized extruded aluminum alloy |

| 7 | Pressure washer | engineering plastic |

| 8 | Limiter | alloy steel |

| 9 | Shaft sealing ring upper | NBR |

| 10 | Upper shaft sliding ring | engineering plastic |

| 11 | Shaft | nickel plated alloy steel |

| 12 | Shaft sliding ring lower | engineering plastic |

| 13 | Shaft O-ring lower | NBR |

| 14 | Plug | NBR |

| 15 | Seal ring of adjusting screws | NBR |

| 16 | Washer of adjusting screw | stainless steel 304 |

| 17 | Lock nut of adjusting screw | stainless steel 304 |

| 18 | Adjusting screw | stainless steel 304 |

| 19 | Piston | die-cast aluminum alloy |

| 20 | Piston guide plate | engineering plastic |

| 21 | Piston sliding ring | engineering plastic |

| 22 | Piston O-ring | NBR |

| 23 | Spring set | spring steel |

| 24 | Cover O-ring | NBR |

| 25 | End cap | cast aluminum with polyester coating |

| 26 | Cover screw | stainless steel 304 |

| 27 | Stop screw | stainless steel 304 |

| 28 | Adapter | carbon steel |

Material sketch of SA pneumatic actuators with return springs

Technical characteristics of the pneumatic distributor 4M310-08 NAMUR

| Design | Spool-type |

| Test pressure (body strength test. Not for operation!), bar | 10 |

| Working pressure (recommended range for normal operation), bar | 1.5 ÷ 8 |

| Valve type | 5/2 five-port, two-position |

| Working medium | purified air (40 µm filter fineness) |

| Operating temperature, °C | 0 to +60 |

| Actuation frequency | 5 cycles per second |

| Manual override | yes |

| Protection rating/insulation class | IP65/F |

| Connection to pneumatic actuator | NAMUR-compliant mounting surface (VDI/VDE3845) |

| Body material | anodized aluminum |

| Effective cross-sectional area, mm2 | 25 (Cv = 1.4) |

| Exhaust port dimensions (vent to atmosphere) | 2 - PT1/4” |

| Air inlet port size (to pneumatic valve) | G1/4” |

| Air outlet port size (to pneumatic actuator) | 2 x Ø19.2 mm |

| Response time, sec | 0.05 |

| Supply voltage, V | 220AC/24DC |

| Coil power | 220VAC – 5.5 VA/24VDC – 4.8 W |

| Weight, kg | 0.35 |

| Average service life, cycles | 10,000,000 |

Overall and installation dimensions of the pneumatic distributor 4M310-08 NAMUR

| A | C | D | E | F | G | H | I | K | L | J | N | M |

| mm | ||||||||||||

| 40 | 24 | 28 | 32 | 40 | 21,5 | 69 | 45 | 17,5 | 135 | 29,3 | 40 | 27 |

Sketch of the dimensions of the pneumatic distributor 4M310-08 NAMUR

Basic materials and parts of the pneumatic distributor 4M310-08 NAMUR

| № | Part Name | Material |

| 1 | Connector | Engineering plastic |

| 2 | Nut | POM + carbon steel |

| 3 | Coil | Copper |

| 4 | Control Elements | — |

| 5 | Plate | Carbon steel |

| 6 | Piston | POM |

| 7 | Control Valve Seat | Engineering plastic |

| 8 | Valve Body | Aluminum alloy |

| 9 | Spool | Aluminum alloy |

| 10 | O-Ring Seal | HNBR |

| 11 | Rear Cover | Engineering plastic |

| 12 | Filter | Synthetic material |

| 13 | Piston | POM |

| 14 | Spring | Stainless steel |

| 15 | Manual Override | Engineering plastic |

| 16 | Rear Seat | Aluminum alloy |

| 17 | Spring Seat | Aluminum alloy |

| 18 | Type C Towing Shackle | 65Mn |

Sketch of the dimensions of the pneumatic distributor 4M310-08 NAMUR

Technical parameters of limit switch unit Elephant APL-410N EX

| Name | Value |

|---|---|

| Limit switch box model | APL-410N EX |

| Service life, years | 10 |

Dimensions and dimensions of limit switch unit Elephant APL-410N EX

| Model | D, mm | D1, mm | H, mm | L, mm | B, mm | M, mm |

| APL-410N EX | 9.5 | 5 | 174 | 177 | 178 | 8 |

Technical parameters of Elephant AFC2000 air treatment unit

| Name | Value |

|---|---|

| Operating pressure, bar | 8 |

| Adjustable pressure range, bar | 0.5 ÷ 9 |

| Filtered particle size, µm | 40 µm |

| Weight, kg | 0.395 |

Dimensions and dimensions of Elephant AFC2000 air treatment unit

| Model | AFC2000 |

| A, mm | 162 |

| B, mm | 88 |

| C, mm | 139 |

| D, mm | 31 |

| E, mm | 53.5 |

| F, mm | 12 |

| G, mm | 8 |

| H, mm | 7 |

| I, mm | 13.3 |

| J, mm | 39 |

| K, mm | 5 |

| L, mm | 40 |

| M, mm | 32 |

| N, mm | 53 |

| O, mm | 29 |

| P, mm | 6 |

| R, mm | 41.5 |

Specifications

Specifications

-

Country of origin

-

Port opening

-

Body material

-

Maximum allowable temperature

-

Connection type

-

Control type

-

Operating environmentWater, Steam, Petroleum Products, Neutral Media, Gaseous Media

-

Type of seal

-

Voltage

-

Explosion-proof

-

Torque

-

Limit switches

-

Type of pneumatic actuator

Reviews (0)

Reviews (0)

Documentation

Documentation

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Frequently Asked Questions

Shipping

What countries do you ship to?

What countries do you ship to?

We currently offer shipping within France and across the EU, as well as international shipping options. If you have a specific destination in mind that is not listed, please don’t hesitate to contact us for more information.

How long will it take to receive my order?

How long will it take to receive my order?

Standard shipping normally takes 3-7 days. Next day shipping is available on all domestic orders (for an additional charge). International shipping times depend on the products and destination (estimated at checkout).

Returns and Refunds

How do I return a product?

How do I return a product?

Items must be returned within 30 days after receiving your order. Items must be returned in the same condition in which they were received, be unworn/unused, have any tags still attached, and include all the original packaging.

How long will it take to receive my refund?

How long will it take to receive my refund?

Refunds are processed within 7 days from when we receive the item(s).